-

Tel:+86 0532-83139309

WhatsApp: +86 15712796572

-

-

No.1-16 Tainan Rd, Wangtai Subdistrict, Huangdao District, Qingdao, China

No.1-16 Tainan Rd, Wangtai Subdistrict, Huangdao District, Qingdao, China

This cutting machine is a multi-functional cutting equipment integrating high efficiency, precision and safety. Designed specifically for cutting various materials such as metal, stone, wood and plastic, it is widely used in many industries including building decoration, machinery manufacturing, hardware processing and stone processing. It can not only meet the high-efficiency needs of mass production, but also adapt to the strict standards of fine processing, making it a core equipment for improving production efficiency and ensuring processing quality.

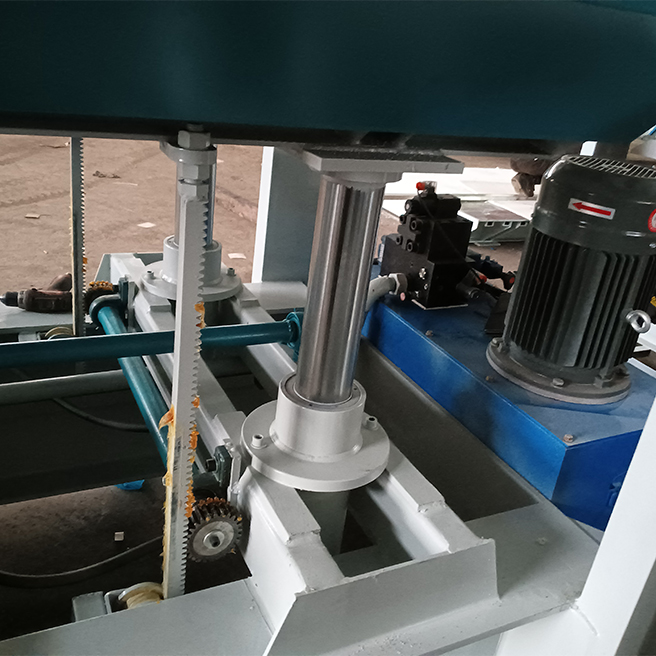

The equipment adopts advanced drive system and cutting technology, equipped with high-precision guide rails and positioning devices. The cutting precision can reach ±0.1mm, which effectively avoids cutting deviation, ensures that each cut is flat, smooth, burr-free and edge-free, greatly reduces subsequent polishing processes, and lowers labor and material costs. The fuselage is integrally formed of high-strength steel, with a stable structure and strong shock resistance, which can withstand high-intensity continuous operation for a long time. Its service life is more than 30% longer than that of ordinary cutting machines, combining durability and practicality.

In terms of operational convenience, the equipment is equipped with a humanized control panel with a simple and easy-to-understand operation process. It supports switching between manual, semi-automatic and fully automatic operation modes, allowing novices to get started quickly. Skilled operators can achieve personalized cutting needs through parameter adjustment, adapting to workpieces of different sizes and thicknesses. At the same time, the equipment has multiple built-in safety protection devices, including overload protection, leakage protection, dust protection and emergency stop button, which effectively prevent potential safety hazards during operation, ensure the personal safety of operators, and comply with national safety production standards.

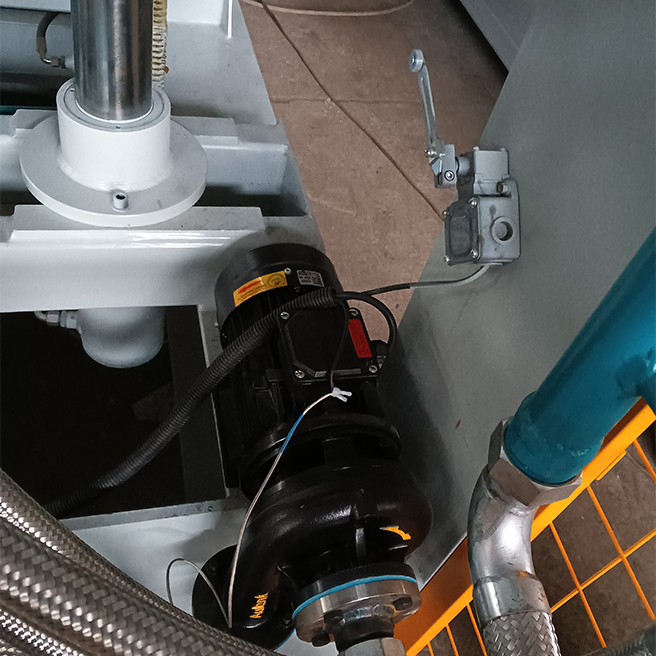

This cutting machine balances energy saving and environmental protection. It adopts a high-efficiency energy-saving motor, whose energy consumption is 20%-30% lower than that of traditional equipment, which can save a lot of electricity expenses in long-term use. The fuselage design meets environmental protection requirements, equipped with a high-efficiency dust removal device, which reduces dust and noise pollution generated during cutting, improves the working environment, and balances enterprise benefits and environmental protection needs. In addition, the equipment supports customized services. According to the specific processing needs of customers, parameters such as cutting size, cutting speed and power configuration can be customized to fully adapt to the personalized processing scenarios of different industries.

We provide comprehensive after-sales services, including free installation and commissioning, technical training, regular inspections and replacement of wearing parts. A professional technical team responds online 24 hours a day to timely solve various problems arising during the use of the equipment, allowing customers to use it more at ease and worry-free.

You First, Exceeding Expectations

To support customers with higher-level production needs, we also provide PRODUCTION LINE INTEGRATION SERVICES and related auxiliary equipment — such as CUTTING, JOINTING, GLUING, ROUTING, EDGE PROCESSING, AND MATERIAL CONVEYING SYSTEMS — according to specific production flows and factory layouts.