-

Tel:+86 0532-83139309

WhatsApp: +86 15712796572

-

-

No.1-16 Tainan Rd, Wangtai Subdistrict, Huangdao District, Qingdao, China

No.1-16 Tainan Rd, Wangtai Subdistrict, Huangdao District, Qingdao, China

This woodworking hot press is specially designed for plate processing, focusing on the bonding, surface treatment and forming processes of wood-based panels, with a wide range of applications. Its processing objects include various plates, such as engineering wood panels like plywood, medium-density fiberboard (MDF), particleboard and joinery board; decorative plates like veneered panels, melamine-faced panels and fireproof boards; and special composite plates like honeycomb panels and aluminum-plastic panels. The corresponding core processing functions mainly include three items: first, the bonding function for lamination of multi-layer plates and curing of adhesives; second, the veneering function for pasting wood veneer, paper or film materials on the surface of plate substrates; third, the forming function for correcting the flatness of plates and ensuring dimensional stability.

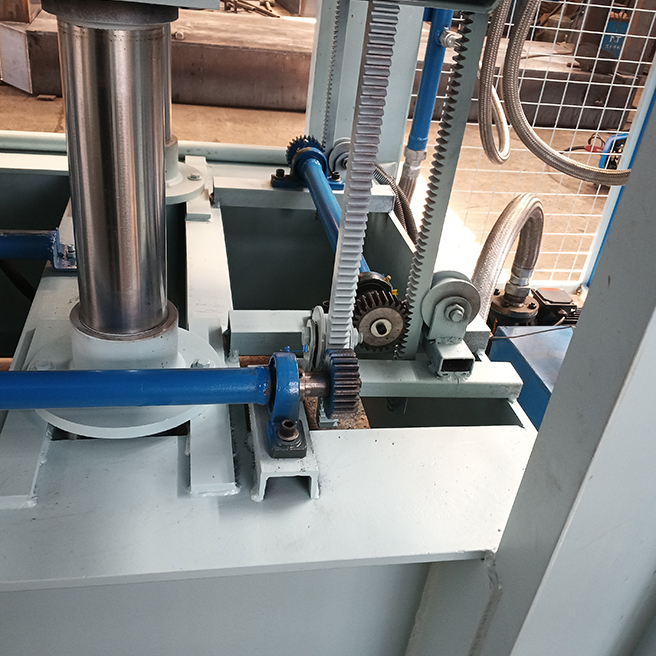

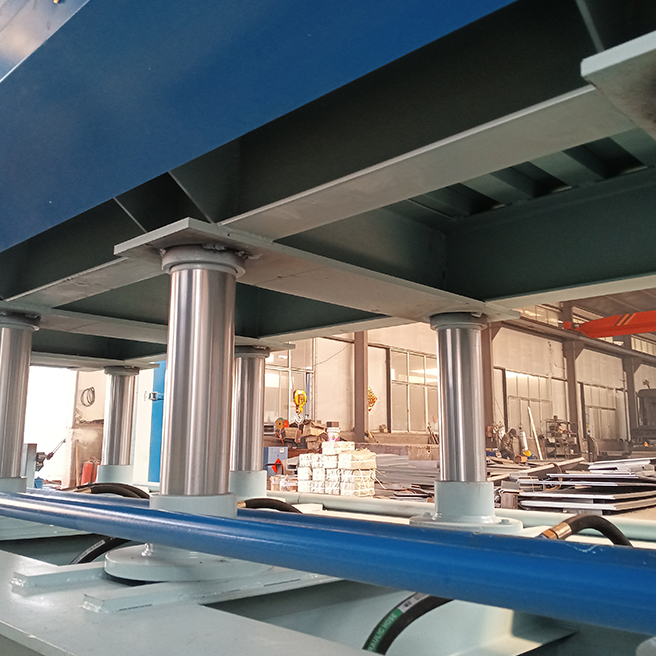

The core technical advantages of this equipment are reflected in three aspects: stable bonding, uniform heating and consistent quality. Specifically, the high-efficiency heating plate can achieve rapid and uniform temperature rise, and the precision hydraulic system can ensure uniform pressure distribution, thus making the processed plates have high bonding strength without delamination or surface defects. At the same time, the plates have excellent flatness and high surface finish, which are suitable for various scenarios such as furniture factories, wood-based panel production plants, wooden door production lines and decorative panel factories.

In terms of model configuration, the HP series woodworking hot press is mainly launched. Instead of listing fixed models, it provides customers with clear selection directions according to "plate size + production capacity level", which is divided into three representative models: medium-duty, heavy-duty and industrial multi-daylight. Among them, the medium-duty hot press has a pressure of 100-150 tons, suitable for furniture factories and decorative panel workshops, mainly used for film covering and veneering of plywood, MDF and particleboard; the heavy-duty hot press has a pressure of 200-300 tons, suitable for wood-based panel factories and wooden door production lines, focusing on the processing of large-size plates, thick plates and multi-layer composite materials; the industrial multi-daylight hot press has a pressure of 300 tons and above, suitable for industrial plate factories and continuous production lines, focusing on the mass production of plywood and film-covered plates. It should be noted that the above are typical configurations, and the equipment can be customized in terms of pressure, workbench size, number of openings, heating method and control system according to the customer's plate size, material type and production capacity.

You First, Exceeding Expectations

To support customers with higher-level production needs, we also provide PRODUCTION LINE INTEGRATION SERVICES and related auxiliary equipment — such as CUTTING, JOINTING, GLUING, ROUTING, EDGE PROCESSING, AND MATERIAL CONVEYING SYSTEMS — according to specific production flows and factory layouts.